“Zero-twist bath towels” are made with little to almost no twisting of the cotton fibers during the spinning process. Traditional towels are made by twisting the cotton threads to make them stronger and more absorbent. However, zero-twist Bath towels use a special spinning technique that doesn’t involve turning the fibers.

As a result, zero-twist Bath towels tend to be softer and more absorbent than traditional towels. They are known for their high absorbency and quick-drying properties. These towels are often favored for their luxurious feel and ability to wick away moisture quickly.

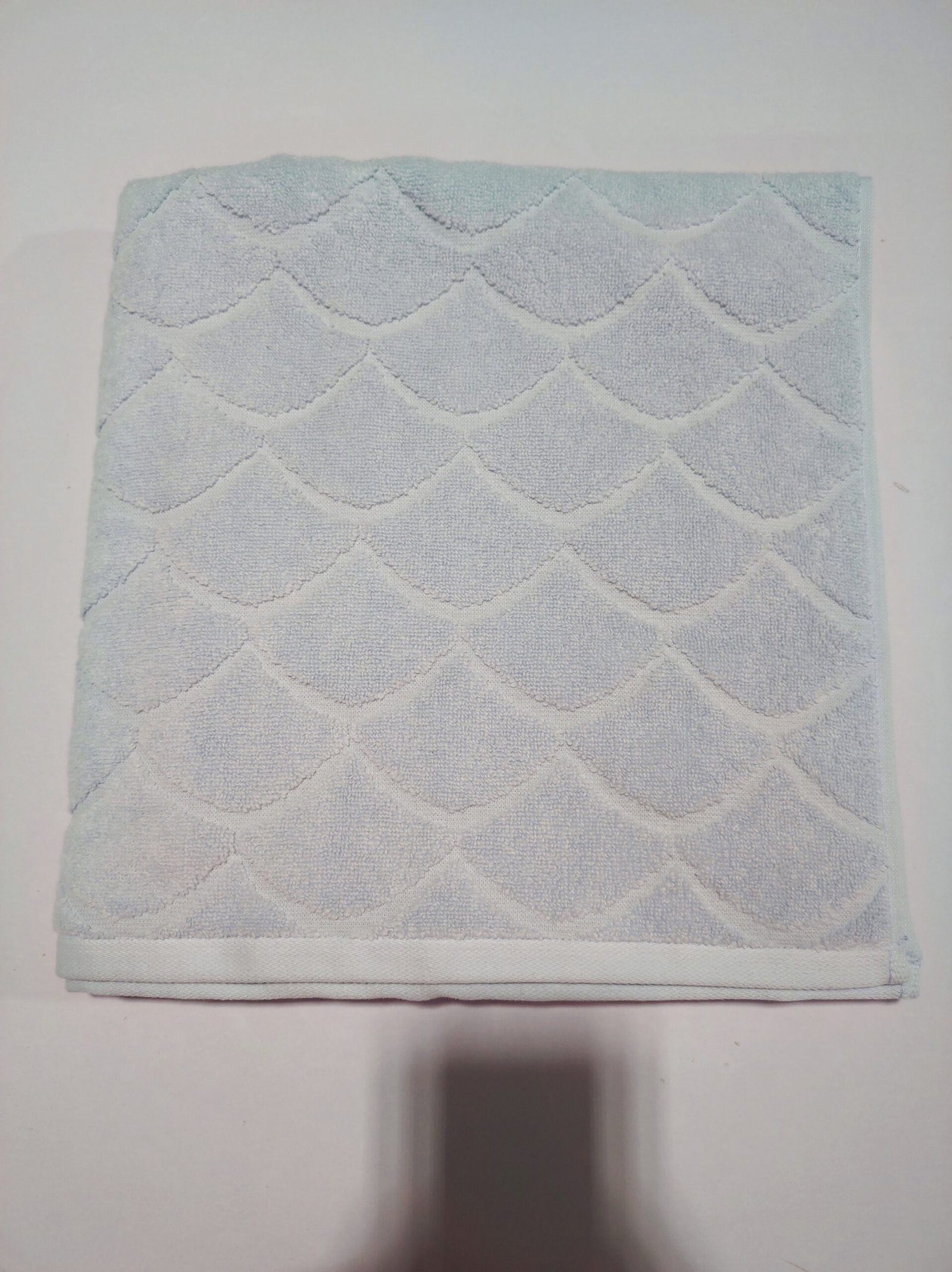

Design selection of "Zero Twist Bath Towels":

Each “zero-twist bath towel” has a design with colors, patterns, and visuals to enhance it. Here, ‘A Luxurious” is no exception. These are the processes that are usually followed to achieve the goal.

Patterns & motifs

Decide on the patterns or motifs that will be used on the towels. Typical design elements include stripes, geometric shapes, floral, abstract patterns, or custom designs related to a particular theme.

Yarn Selection for "Zero-Twist Bath Towels"

Pile Yarn selection for "zero twist Bath Towels":

Plush “Zero-twist bath towels” are customarily made with a lower yarn count in the pile section of the towel. A lower yarn count suggests that the yarns in question are plumper and, therefore, have a lower twist number per inch. Bath towels are generally softer and plusher, which makes lower yarn counts in the pile portion of the towel a common preference. The standard count of the yarns for zero-twist bath towels in the pile section is between 10s and 16s, where 10s is thicker and more luxurious. A coarser towel with a lower yarn count is much more fluffy and better for soaking up moisture.

warp or Ground Yarn selection for "zero twist Bath Towels":

In the case of ‘zero twist bath towels,’ the ground part is made to have lower twill texture counts, which are of finer yarn. These finer yarns, with higher numbers, are twisted to provide structure and strength to the base fabric of the towel. Various manufacturers can design these towels using a common yarn count between 16s to 30s or higher, even for the ground portion of zero-twist bath towels. This is depending on the specific manufacturer and the desired characteristics. Finer yarn counts in the ground portion help maintain the towel’s shape, strength, and durability while enabling the soft and absorbent pile to remain plush.

Weft Yarn selection for "zero twist Bath Towels":

Bath towels with zero twist feature plush absorbent piles while maintaining a particular shape through finer yarn counts in the weft portion. These towel grounds also use finer counts. These finer and sometimes higher orders are further twisted to prevent the fabric of the towel from being flimsy. These counts ensure that the towel is highly absorbent. The common counts for the weft portion in the different towel designs and manufacturers can range between 12s to 30s.

Dyes type used for the "Zero twist Bath towels:"

Luxurious “Zero-twist bath towels ” are typically dyed using reactive dyes. Reactive dyes, including towels, are a common choice for cotton textiles because they chemically bond with the cotton fibers. This type of dye offers several advantages.

Vibrant Colors: Reactive dyes are known for producing vibrant and long-lasting colors, which is desirable for towels that need to maintain their appearance through repeated washings.

Color Fastness:

They provide excellent colorfastness, meaning the colors are less likely to fade when exposed to light or during washing.

Softness:

Reactive dyes retain the towels’ softness and absorbency since they do not create a thick, stiff layer of color on the fabric.

Durability:

The chemical bond formed with the cotton fibers makes the color more resistant to fading and washing, ensuring the towels look suitable for an extended period.

Reactive dyes are well-suited for achieving the vibrant and long-lasting colors desired in bath towels, including zero-twist bath towels.

Finishing techniques used for the "Zero Twist Bath Towels":

The finishing techniques used for Luxurious “zero-twist bath towels” are designed to enhance their softness, absorbency, and overall quality. Standard finishing techniques include:

Softening Agents:

All manufacturers use softening agents in the final rinse to enhance the towels’ softness. These agents can help create a luxurious and comfortable feel.

Tumble Drying:

After washing, the towels are often tumble-dried, which not only fluffs up the fibers but also helps maintain their softness and absorbency.

Stitching techniques used for the "Zero Twist Bath Towels":

1-Slitting process for "zero twist bath towels":

The “slitting process” generally refers to the production of towels that involves cutting or slitting big rolls of fabric into smaller panels and individual towel sizes into one panel. This process is required to make custom-sized towels for the consumers. This is the way the slitting process happens:

Large Rolls of Fabric:

Towel fabric is often produced in large rolls, typically in wider widths

Measurement and Marking:

In the slitting process, the fabric is measured and marked to the desired width for the towels. This width corresponds to the final size of the towels, such as hand towels, bath towels, or washcloths.

Cutting or Slitting:

Specialized machinery, such as cutting or slitting machines, is used to cut the fabric along the marked lines. This separates the large roll into smaller rolls or sheets, each of which will become an individual towel panels.the Texpa ,Azeemo, schmale , Bando, Tept machines are used for this purposes..

2-the length hemming process for "zero twist bath towels":

The purpose of length hemming zero-twist bath towels is to make them secure and durable for end use. The steps below are involved in making the hem.

Preparation:

The fabric will be cut to a predetermined length before the hems are sewn onto the towel. It will also be checked for flaws before sewing begins.

Folding:

The towel is folded half lengthwise, ensuring the raw edges are aligned evenly.

Hem Stitching:

They manufacture sewing machines, such as supervisor machines and manufacturer’s towels.

A specialized sewing machine outfitted with a chain stitch 401 or single needle lock stitch is utilized to sew along the border of the folded towel. This stitch encases the border and inhibits fraying.

The Texpa, Azeemo, Schmale, Bando, and Tept single-needle machines accomplish this.

3-the cross-cutting process for "zero twist bath towels":

Cross-cutting in the context of zero-twist towels refers to cutting the towel fabric across its width to create towels. Here are the steps involved in the cross-cutting process:

Preparation:

Large rolls or panel sheets of zero-twist towel fabric are prepared for cutting.

Measurement and Marking:

The fabric is measured and marked to the desired width for each towel. The width will depend on the specific towel size, such as hand towels, bath towels, or washcloths.

Cutting :

Specialized cutting equipment, such as rotary cutters or straight blades and scissors, is used to cut the fabric along the marked lines. This separates the large roll or panel sheets into smaller pieces, each of which will become an individual towel.

4-the cross-stitching process for "zero twist bath towels".

A specialized sewing machine, often equipped with a single needle lock stitch or serge stitch, is used to stitch along the diagonal fold, securing the hem. This process also named as End hemming or cross stitching of the towel.

5-The Grading, Finishing & Packing process of "Zero Twist Bath towels":

The grading process of zero-twist bath towels includes assessing their quality, size, and general appearance, as these are the criteria under which the towels will be ranked and classified. This grading system helps guarantee that the packaged and marketed towels to the end users meet specific established criteria. Here is what the grading process looks like in general.

Inspection:

Towels are carefully inspected according to the AQL standards for defects, flaws, or irregularities in the fabric, stitching, or embroidery (if applicable). The towels are checked for stains, loose threads, and any other imperfections.

Size Verification:

Towels are measured to confirm that they meet the specified dimensions for the particular size (e.g., hand towels, bath towels, washcloths.Any towels that are too small or too large are separated.

Color Consistency:

The color of the towels is assessed to ensure that it matches the desired shade or pattern. This is particularly important for towels with specific color requirements.

GSM check:

A towel may also go through the GSM test with GSM cutter and manual process.

Color Consistency:

Towels may undergo absorbency tests to ensure they meet the desired level of functionality.

Hemming and Stitching Inspection:

The quality of hems and stitching is assessed, ensuring they are neat, secure, and even.

Reprocessing (if necessary):

Towels that do not meet the standards may undergo reprocessing or resorting, including fixing defects or re-hemming.

Packaging:

Towels are bundled based on their grade, size, and other details. First-quality towels are set for sale, while seconds or towels with slight irregularities may be disposed of at factory seconds or retail outlets.

The classification helps to ascertain defects in the towels so customers don’t have to bother with substandard quality services. At the same time, it assists the manufacturer in containing costs relative to the level of quality achieved through measuring and controlling the overall expenses.

frequently asked questions for zero twist bath towels:

What are zero twist bath towels?

Zero-twist bath towels are made from long-staple cotton fibers twisted together without adding any extra twist. This unique construction makes them exceptionally soft, plush, and absorbent.

How do zero twist towels differ from traditional towels?

Traditional towels are made with twisted yarns, which can make them feel denser and heavier. In contrast, zero-twist towels feel lighter, softer, and more luxurious against the skin.

Are zero twist towels more absorbent than regular towels?

Yes, zero twist towels are often more absorbent than regular towels because the lack of twist in the yarn allows more surface area to come into contact with water, helping them to absorb moisture more effectively

What are the benefits of using zero twist towels?

Some benefits of using zero-twist towels include their exceptional softness, high absorbency, quick drying time, and luxurious feel. Due to their high-quality construction, they are also more durable than traditional towels.

How should zero twist towels be cared for to maintain their quality?

To properly care for zero-turn towels, they should be washed in warm water with a gentle detergent and skipped fabric softeners, which would damage absorbency. Low-heat tumble drying or air drying is recommended to preserve the towels’ softness and fluffiness.

Very informative and very impressive.

Very informative and impressive.