the Color fastness to sunlight is a measure of a material’s or substance’s ability, commonly a fabric or dye, to resist fading or alterations in color when subjected to sunlight. This characteristic holds particular significance across various industries, with a notable emphasis in textiles, where fabrics are frequently utilized in outdoor environments or encounter sunlight throughout their usage.

Sunlight encompasses ultraviolet (UV) radiation, a factor that can exert a substantial influence on the color steadfastness of materials. Extended exposure to sunlight over time has the potential to induce fading in colors, resulting in a lackluster or washed-out visual appearance. Hence, the consideration of color fastness to sunlight becomes integral in assessing both the endurance and aesthetic resilience of colored materials.

the Scope of color the fastness to sunlight test:

Colorfastness to sunlight is a testing method designed to evaluate how well a material retains its original color when exposed to sunlight or other forms of light. This testing is applicable to various materials, including textiles, artworks, and products where color stability is crucial.

the Purpose of the color fastness to sunlight test:

The primary purpose of color fastness to sunlight testing is to assess the durability and longevity of colors in materials under prolonged exposure to light. This testing helps manufacturers, designers, and consumers make informed decisions about the suitability of materials for specific applications, ensuring that products maintain their visual appeal and quality over time. Additionally, it aids in the development of materials that can withstand environmental conditions, contributing to the overall sustainability and performance of products in various industries.

Equipments and Materials for the Color fastness to sunlight test:

- ISO standards usually call for a xenon arc lamp or a carbon arc lamp as the spotlight. These lamps replicate the sun’s brilliance and other lighting conditions, creating a controlled environment for our color endurance experiment.

- Colorimeters, Fade-o-meter, Whether-o-meter

- DATA Color

- Blue Dyed Wool scale

- Fabric swatch

ISO Test Procedure for the color fastness to sunlight:

1-Sample Preparation:

Cut representative samples (5 cm by 10 cm) from the material.

2-Marking the Swatch

Mark one side of each swatch that will be exposed to light. This helps in later comparisons

3-Mounting on Sample Holder:

Affix the swatches on a sample holder or frame, ensuring secure placement.

4-Exposure Setup:

Place the sample holder in the exposure apparatus, positioning it to allow exposure to the simulated sunlight.

5-Securing Hidden Side:

Arrange the swatches in a way that one side (marked for exposure) is fully exposed to light, while the other side is shielded or covered during the exposure period.

6-Light Exposure:

Activate the sunlight simulator to expose the marked side of the swatches for the specified duration, 24 hours to 74 hours simulating sunlight conditions.

7-Record Keeping:

Document the setup details, including which side was exposed and which side was shielded. This information is vital for accurate evaluation.

8-Assessment of Color Change:

After exposure, assess the color change by comparing the exposed side to the hidden side visually or using instruments such as

- colorimeters

- Fade-o-meter

- Whether-o-meter

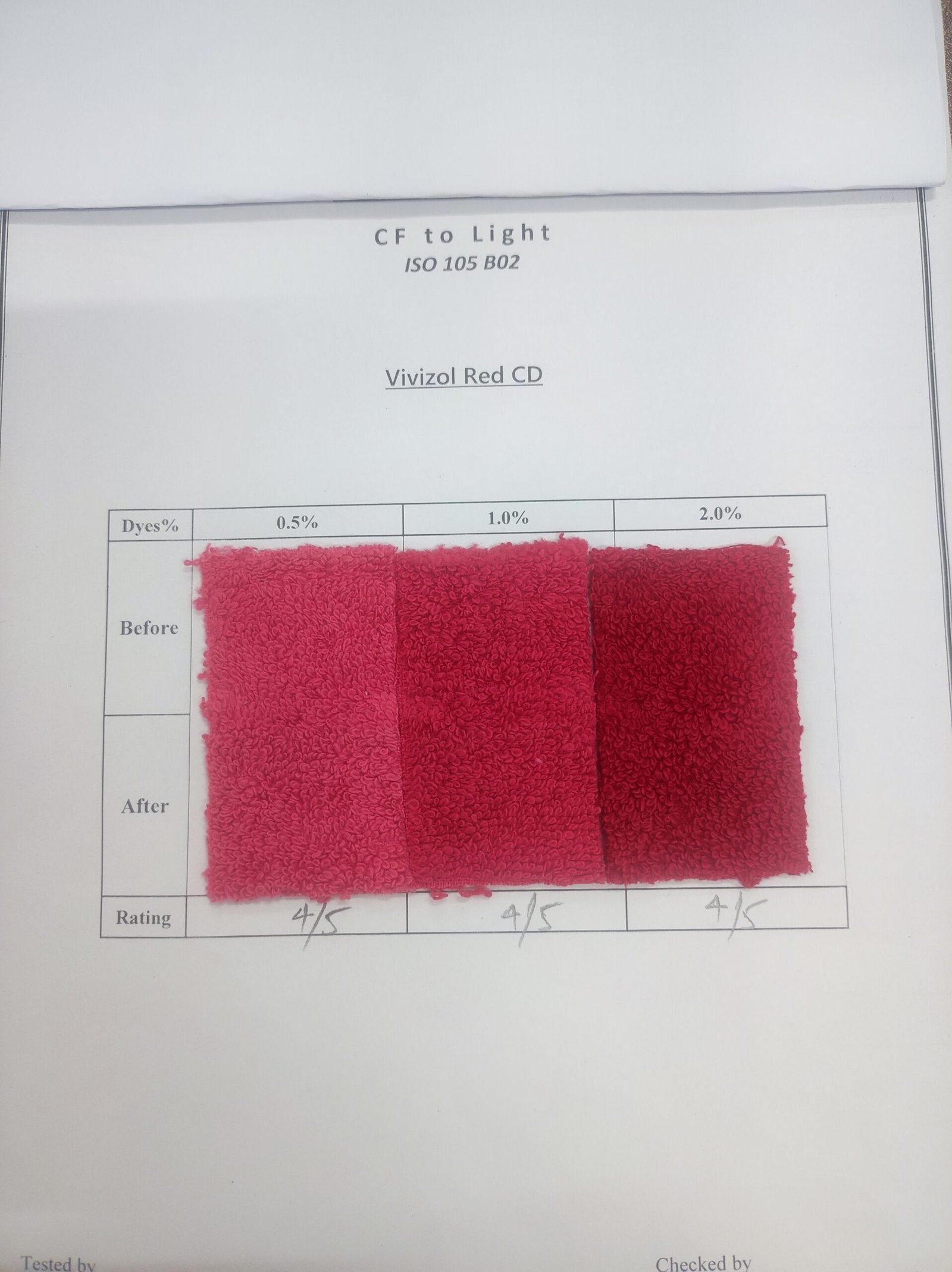

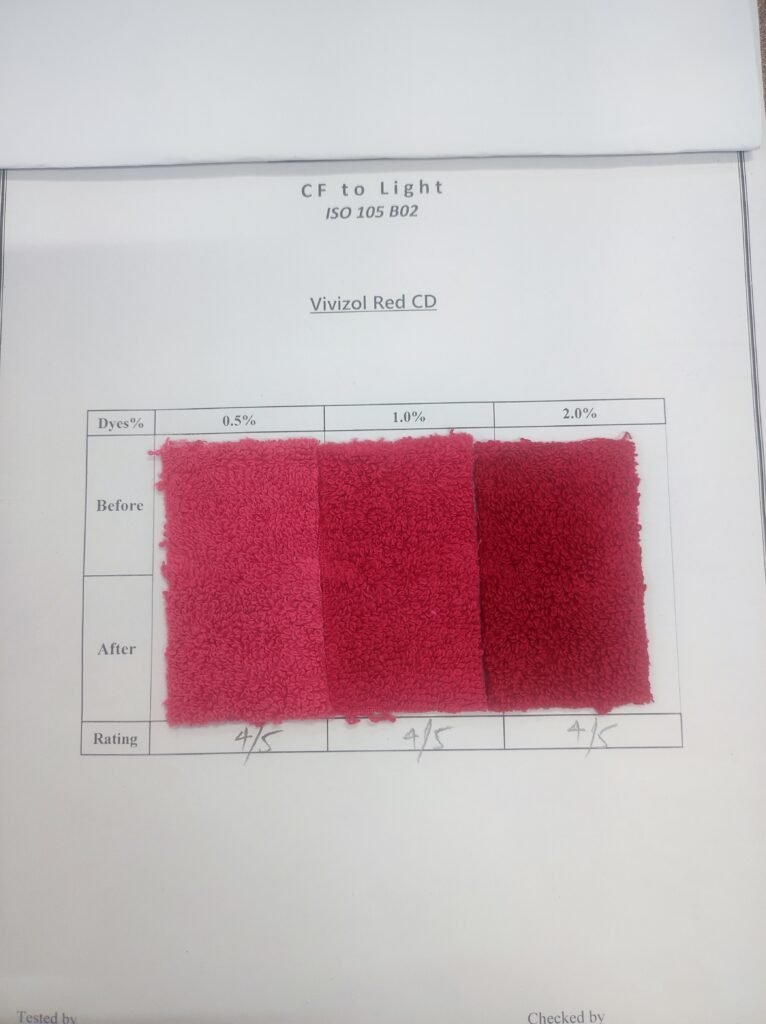

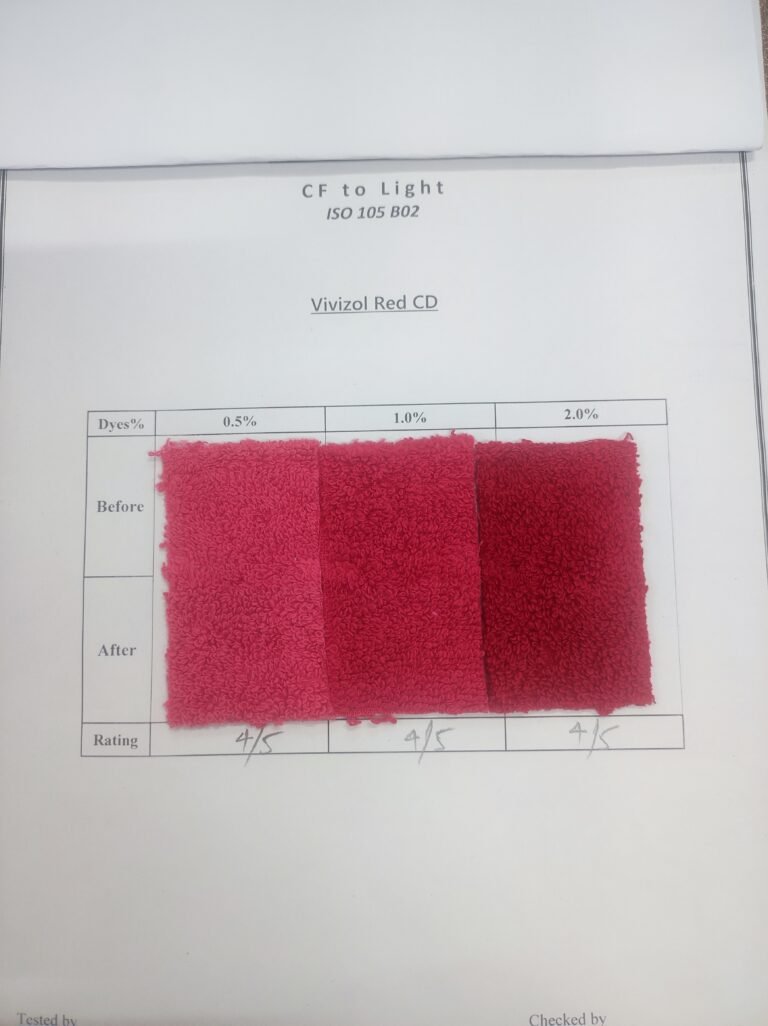

Greyscale Rating:

Rate the color change using a blue-dyed wool sample s, following the standards provided by ISO 105-B02 or AATCC Test Method 16. Normally the blue dyed wool sample has 1(poor)-8(excellent) grades.

Grades | Degree of Fading | Remarks |

|---|---|---|

1 | Very extensive Fading | Very Poor |

2 | Extensive Fading | Poor |

3 | Series Fading | Fair |

4 | Considerable Fading | moderate |

5 | moderate Fading | good |

6 | Slight Fading | very good |

7 | very Slight Fading | excellent |

8 | No Fading | Remarkable |

the change in Shade depth Analysis after the Color fastness to sun light test:

the change in Shade depth analysis can be effectively conducted using advanced technologies such as the Computer Color Matching System (CCMS) or the DATA Color Matching System. This involves establishing a baseline by inputting the unexposed part of the specimen as the standard. Subsequently, the exposed part of the specimen is input, and a comparative analysis of the results is performed. Through this process, the degree of fading for each color can be precisely determined, providing valuable insights into the material’s colorfastness under varying exposure conditions.

Application of the Color fastness to sunlight:

Textile Industry:

In the textile industry, color fastness to sunlight testing is crucial to ensure that fabrics used in clothing, upholstery, and outdoor textiles maintain their color vibrancy and resist fading when exposed to sunlight. This helps manufacturers produce durable and aesthetically pleasing textiles.

Art and Museum Conservation:

Artworks displayed in museums or galleries often undergo color fastness to sunlight testing to assess how well pigments and dyes resist fading over time. This is vital for preserving the original appearance and value of art pieces.

Product Packaging:

Many consumer products utilize color for branding and aesthetic appeal on packaging. Color fastness testing ensures that product packaging maintains its visual appeal on store shelves, even when exposed to light during transportation, storage, and display.

Furniture and Interior Design:

Fabrics used in furniture and interior design elements, such as curtains and upholstery, undergo color fastness testing. This ensures that these materials can withstand light exposure, maintaining their colors and patterns in homes and commercial spaces.

Automotive Industry:

The automotive industry employs color fastness testing to assess the durability of interior fabrics and components. This ensures that the colors in vehicle interiors remain vibrant and do not fade over time due to exposure to sunlight through windows.

Frequently Asked Questions on the color fastness to sunlight:

Why is Color Fastness to Sunlight Important?

Colorfastness to sunlight is crucial because it assesses how well materials retain their original colors when exposed to sunlight. This is essential in industries like textiles, art conservation, and product packaging to ensure durability, aesthetic appeal, and longevity.

How is Color Fastness to Sunlight Tested?

The testing is often done using specialized equipment such as xenon arc lamps or carbon arc lamps to simulate sunlight. The material samples are exposed to controlled light conditions, and the degree of color change is evaluated visually or with instruments like colorimeters.

What Factors Influence Color Fastness to Sunlight?

Several factors can impact color fastness, including the type of dye or pigment used, the material composition, environmental conditions, and the presence of finishing treatments. Understanding these factors is crucial for designing materials with enhanced color stability.

What Standards Govern Color Fastness to Sunlight Testing?

ISO (International Organization for Standardization) and AATCC (American Association of Textile Chemists and Colorists) provide widely recognized standards for color fastness testing, including specific methods such as ISO 105-B07 and AATCC Test Method 125. Adhering to these standards ensures consistency and reliability in testing procedures.

.