Table of Contents

Brief Introduction of Yarn count:

The yarn count is an important parameter for the textile industry. It defines the thickness and weight of the yarn and directly impacts the final fabric’s texture, strength, and appearance. Accurately measuring the yarn count is important to maintain the quality and consistency of textile products.

The Purpose of the Test:

This experiment aims to assess the count of several yarn samples using different measurement systems. it can be determined through various systems, including the metric system (Tex) and the English system (Ne). In simple terms, a higher number represents finer yarn, while a lower number signifies thicker yarn. Understanding these counts is crucial for manufacturers to select the most suitable materials for their production needs.

The Scope of The Test:

This report outlines the principles and methods used to measure yarn count. It includes a thorough description of the equipment, procedures, calculations, results, and conclusions drawn from the experiment.

The Apparatus used for the Test:

1-The cone of yarn

2-Wrapping Reel

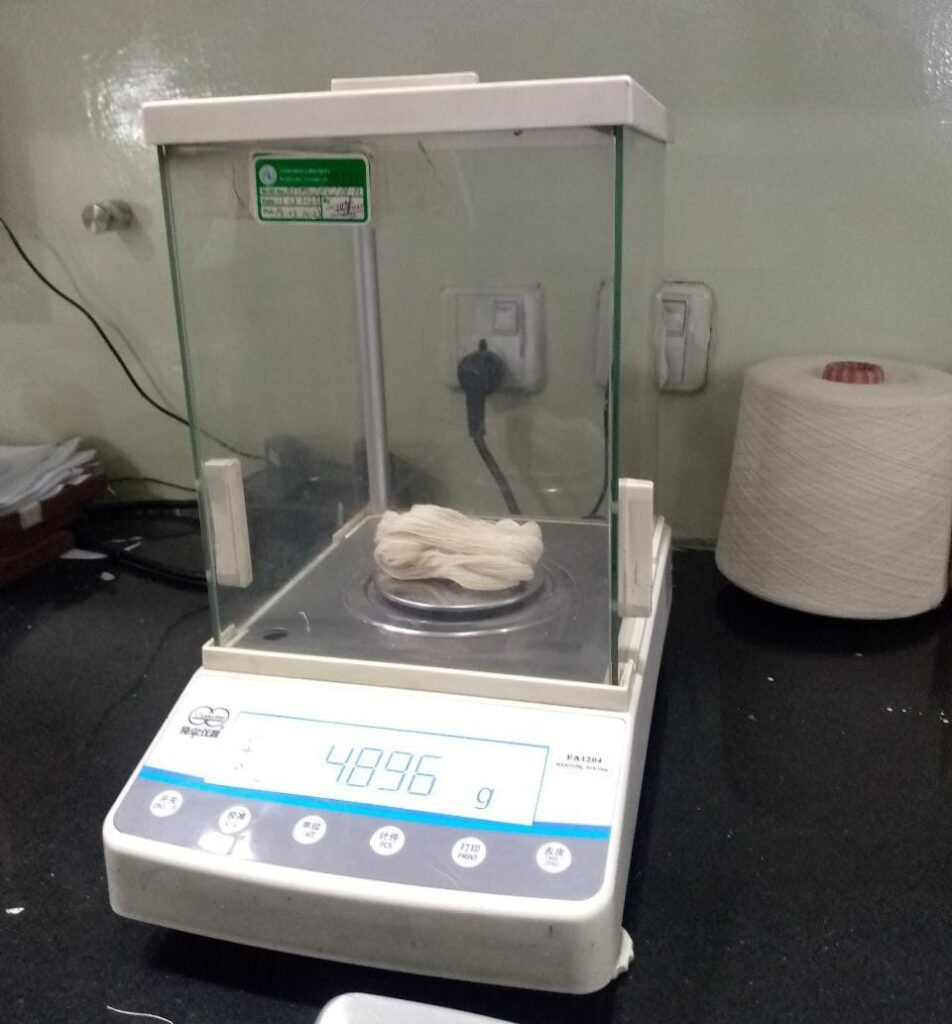

3-Weighing scale

4-calculator

The Procedure of The Test:

- Begin by taking a cone of yarn.

- Next, place the yarn onto the skein of the wrapping machine.

- Set the machine to perform 80 rotations.

- Press the start button to begin the rotation.

- The machine will automatically stop after 80 rotations, creating one lea of yarn.

- Finally, weigh the lea using the machine’s weighing scale.

The Formula of Yarn count Test:

Yarn count = 64.8 / weight of lea

if the weight i s lea is 4.896 then count yarn will be

64.8/4.896 = 13.2

The Yarn count is 13.2

Q: From where we get the value (64.8) in that formula?

The value 64.8 is actually a conversion factor that converts the length from yards to meters.

1 yard = 0.9144 meters

840 yards = 768.16 meters

And then divided by 12 (since there are 12 inches in a yard), resulting in approximately 64.8.

The Conclusion:

First, we take a cone of yarn and use a wrapping machine to create a lea. Once the lea is prepared, we measure its weight using a weighing machine. We then use this weight to calculate the yarn count.

Factors Affecting Yarn Count:

Several factors influence the calculation of yarn count, starting with the type of fiber used. Different fibers have unique characteristics that affect their weight and thickness. For instance, cotton is lighter than wool, leading to varied counts.

The spinning process also plays a crucial role. Various techniques can change the density and twist of the yarn. A tighter spin generally results in finer yarns, while looser spins yield thicker ones.

Tension during production impacts how tightly fibers are held together as well. Higher tension often leads to a more consistent count but may compromise flexibility.

Additionally, twists added during spinning enhance strength but can alter overall dimensions. Each factor interacts dynamically to create distinct final products tailored for specific uses or preferences in texture and durability.yarn count not just beneficial, but essential for success in any fiber arts endeavor!

Common Mistakes in Calculating Yarn Count :

Calculating yarn count can be tricky, and mistakes often occur. One common error is mismeasuring the length or weight of the yarn. Precision is crucial; even a small discrepancy can lead to significant differences in count.

Another mistake involves misunderstanding the units used for calculation. Yarn count systems vary by region and fiber type, so clarity on whether you’re using metric or imperial units is essential.

Many overlook the effects of moisture content as well. Yarn’s weight changes when it absorbs humidity, which impacts accuracy. It’s best to weigh yarn in a controlled environment.

Lastly, failing to account for twist and tension during spinning can skew results. Always ensure that your sample reflects true conditions from production processes.

By being aware of these pitfalls, you can enhance your calculations and achieve better results with your projects.

2 thoughts on “The number 1 Formula Behind Yarn Count : How to Calculate It Effectively?”